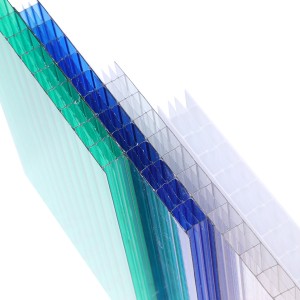

SINHAI Construction Materials plastic UV protection hollow polycarbonate roof sheet

Product Detail

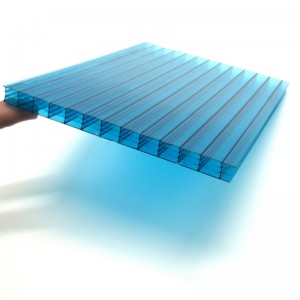

The spontaneous combustion temperature of PC polycarbonate sheet is 630℃. According to the test of the National Fireproof Building Material Quality Supervision and Inspection Center, PC sheet has a combustibility of GB, which is a flame-retardant engineering material. Chemical resistance to corrosion. Polycarbonate hollow sheet has good chemical resistance to corrosion, and can withstand the erosion of various organic acids, inorganic acids, weak acids, vegetable oils, neutral salt solutions, aliphatic hydrocarbons and alcohol at room temperature. Heat and cold resistance. The lexan polycarbonate sheet has good temperature resistance, can adapt to various severe weather changes from severe cold to high temperature, and maintains various physical performance indicators within the range of -40°C to +120°C. Photochemical. PC hollow sheet have the highest light transmittance in the visible light and near-infrared spectrum. Depending on the color, the light transmittance can reach 12%-88%. Anti-uv and anti-aging. The surface of the hollow polycarbonate sheet contains an anti-uv co-extruded layer, which has good outdoor weather resistance and maintains good optical and mechanical properties after long-term use. The twin wall polycarbonate sheet is light in weight, 1/12-1/15 of the same glass, safe and not broken, easy to handle and install, can reduce the weight of the building, simplify the structure design, and save installation costs.

| Material | 100% virgin bayer/sabic polycarbonate resin |

| Thickness | 2.8mm-12mm |

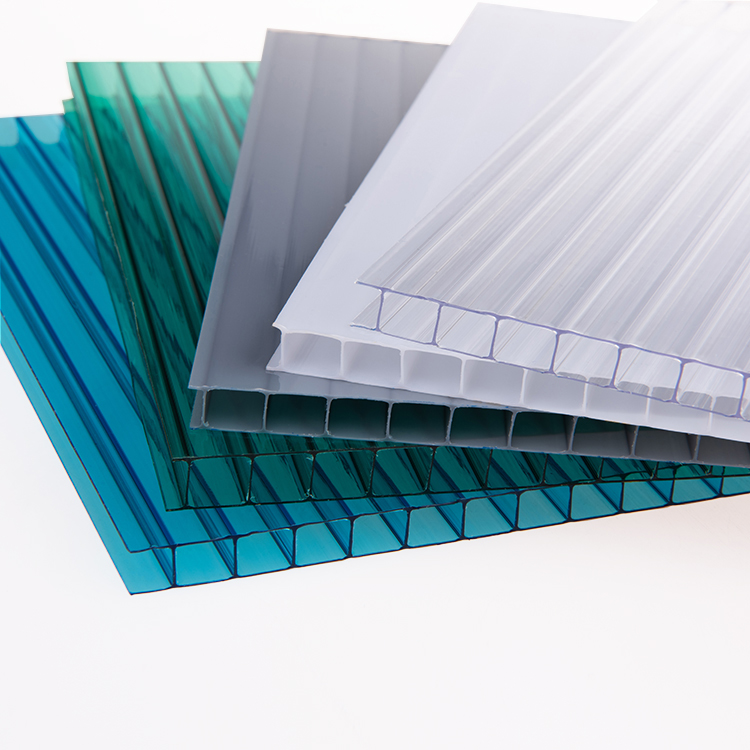

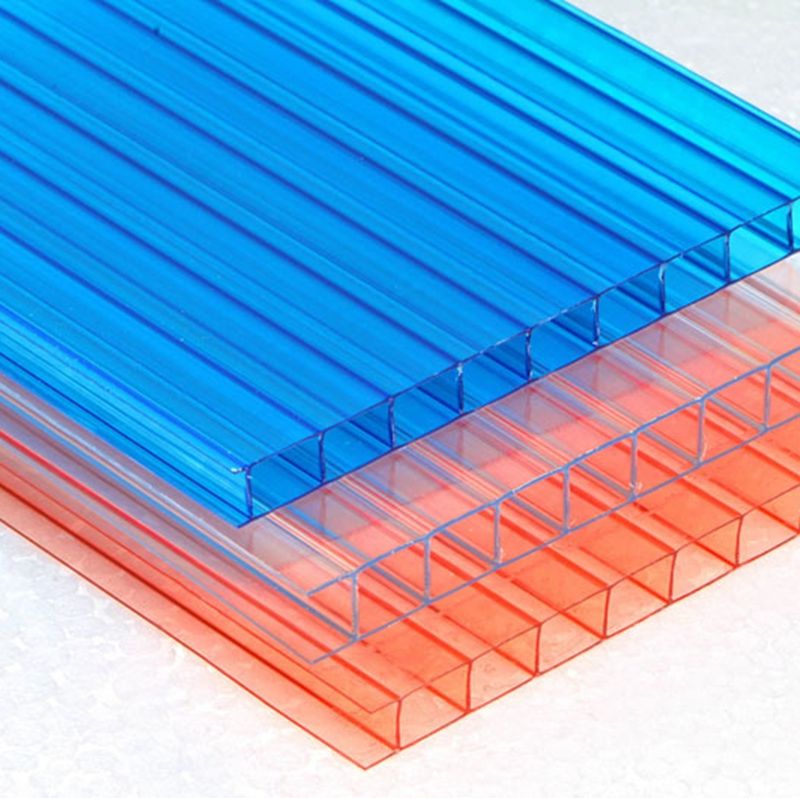

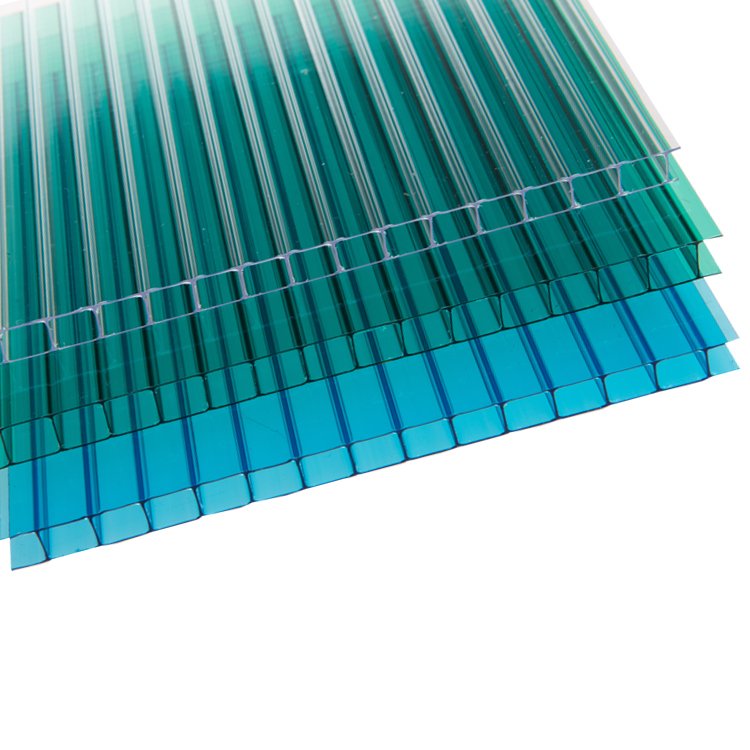

| Color | Clear, Blue, Lake Blue,Green, Bronze, Opal or Customized |

| Width | 1220, 1800, 2100mm or customized |

| Length | No limit |

| Warranty | 10-Year |

| Technology | Co-extrusion |

| Price term | EXW/FOB/C&F/CIF |

|

Thickness(mm) |

Weight (kg/m²) |

Width (mm) |

U Value (w/m²k) |

Light transmission (%)clear |

Min bending radiums (mm) |

Min span (mm) |

|

4 |

0.95 |

1220/2100

|

3.96 |

78 |

700 |

1500 |

|

6 |

1.3 |

3.56 |

77 |

1050 |

1800 |

|

|

8 |

1.5 |

3.26 |

76 |

1400 |

2000 |

|

|

10 |

1.7 |

3.02 |

73 |

1750 |

2700 |

|

U.M. |

PC |

PMMA |

PVC |

PET |

GRP |

GLASS |

|

| Density |

g/cm³ |

1.20 |

1.19 |

1.38 |

1.33 |

1.42 |

2.50 |

| Strength |

K.J/m² |

70 |

2 |

4 |

3 |

1.2 |

- |

| Modulus of elasticity |

N/mm² |

2300 |

3200 |

3200 |

2450 |

6000 |

70000 |

| Linear thermal expansion |

1/℃ |

6.5×10-5 |

7.5×10-5 |

6.7×10-5 |

5.0×10-5 |

3.2×10-5 |

0.9×10-5 |

| Thermal conductivity |

W/m.k |

0.20 |

0.19 |

0.13 |

0.24 |

0.15 |

1.3 |

| Max.service temperature |

℃ |

120 |

90 |

60 |

80 |

140 |

240 |

| UV transparency |

% |

4 |

40 |

nd |

nd |

19 |

80 |

| Fire performance |

- |

very good |

poor |

good |

good |

poor |

fireproof |

| Resistance to weathering |

- |

good |

very good |

poor |

fair |

poor |

excellent |

| Chemical compatibility |

- |

fair |

fair |

good |

good |

good |

Very good |