The manifestation of aging is that the originally transparent polycarbonate sheet becomes dirty, the light transmittance decreases, and the color turns yellow during use; the internal manifestation of aging is the decline in physical properties, the loss of the originally high impact strength and tensile strength, and it becomes easy to crack. The fake polycarbonate sheets we often see become very transparent after a period of use, some begin to crack, and even become brittle, which are all manifestations of aging. Delaying the aging time means extending the service life.

The structure of the polycarbonate sheet is made of polycarbonate raw materials, which is a polymer material. The most important factor affecting the life of the polycarbonate sheet is ultraviolet rays. Ultraviolet rays in nature can chemically degrade polymer materials, which is generally called aging. Therefore, only by solving the problem of ultraviolet rays can we talk about the length of service life.

The main reason for the aging of polycarbonate sheets is that the quality of the polycarbonate sheets used is too poor. For example, the polycarbonate sheets are processed with recycled materials, which will greatly reduce the service life of the polycarbonate sheets. The later maintenance is not done well and regular maintenance is not carried out. In addition, the anti-ultraviolet layer on the surface of the polycarbonate sheets is damaged under very harsh conditions, which accelerates the aging of the polycarbonate sheets.

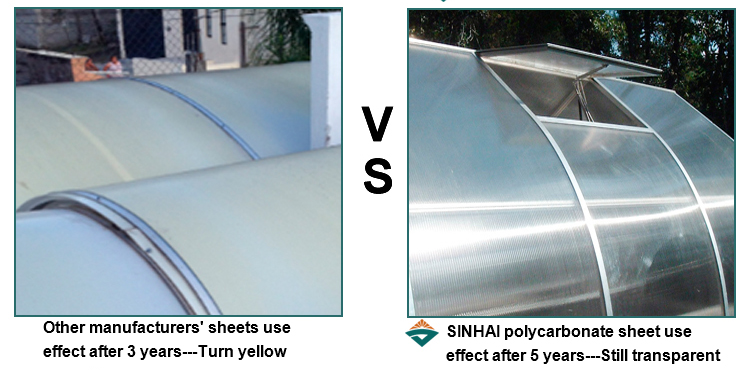

It is very simple to judge whether the polycarbonate sheet is aging. If the color turns yellow, the light transmittance of the product decreases, and the board becomes brittle and prone to cracking and perforation, then the board has aged. You should consider replacing the polycarbonate sheet at this time. This is because the UV layer on the surface of the polycarbonate sheet is damaged. The polycarbonate sheet is exposed to the sun for a long time. The long-term exposure to ultraviolet rays will make the physical properties of the board worse and worse, and finally it will not be able to be used normally.

Remind everyone that if you want to extend the service life, it is recommended that you use the polycarbonate sheet produced by the brand new imported materials with quality assurance. If you use ordinary quality, you must replace it in time after using it for a few years, which will not only take time but also increase your cost. Therefore, friends who buy polycarbonate sheets are reminded that if you want to extend the service life, you must choose a good polycarbonate sheet manufacturer.

Company Name: Baoding Xinhai Plastic Sheet Co.,ltd

Contact Person: Sale Manager

Email: admin@cnxhpcsheet.com

Phone/Wechat/Whatsapp: +8619932587617

Country: China

Website: https://www.xhplasticsheet.com/

Post time: May-30-2024