10mm polycarbonate sheets are made of imported polycarbonate raw materials and processed by high-tech infrared protection special process. The sheet surface is evenly distributed with a high-concentration UV co-extruded anti-ultraviolet layer, which can block the passage of ultraviolet rays and protect the stability of the product to ultraviolet radiation, long-term weather resistance, protect indoor objects, and extend the life of the board.

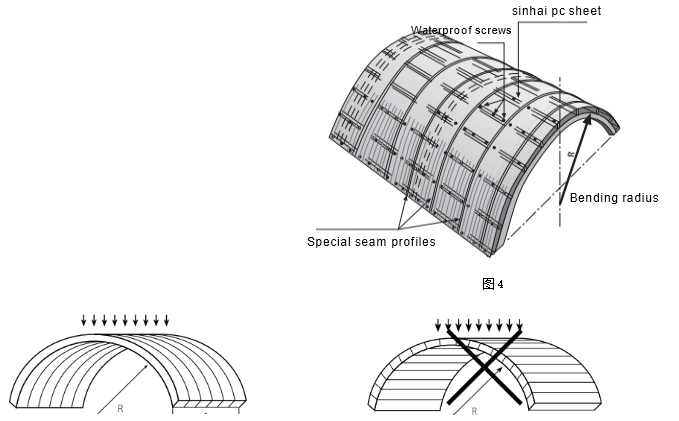

Unique installation method of 10mm polycarbonate sheets:

First, the polycarbonate sheets should be bent in the direction of force and must not be bent horizontally. The bending radius is the thickness of the sheet: less than 175 times for hollow double wall polycarbonate sheet, less than 185 times for three-layer polycarbonate sheets, and less than 200 times for four-layer polycarbonate sheet. The bending radius of solid polycarbonate sheets is also less than 175 times the thickness. It is strictly forbidden to fix the bent parts of the sheet with screws.

Second, when installing hollow polycarbonate sheets and solid polycarbonate sheets, thermal expansion gaps must be reserved at the joints between sheets according to the size of the sheet. The thermal expansion coefficient is 0.065mm/m℃. It is strictly forbidden to fix directly through the board with self-tapping screws, rivets, etc. If it is necessary to pass through, you must drill an enlarged hole on the board with a diameter larger than 100% of the diameter of the self-tapping screw or rivet, and then lower the self-tapping screw or rivet through the center of the enlarged hole to ensure that the sheet can freely expand and contract in any direction.

Third, the sealant in contact with the hollow polycarbonate sheet must be neutral silicon copper glue. It is strictly forbidden to use alkaline, acidic, and chemically unknown sealants containing solvents. Avoid direct contact between the hollow polycarbonate sheet and chemical solvents, solutions and volatile gases. If you use paint diluted with thinners to spray the polycarbonate hollow sheet support frame, you must install the polycarbonate hollow sheet after the paint is completely dry. It is strictly forbidden to use paint diluted with thinners to brush the steel frame of the installed polycarbonate hollow sheet.

Fourth, the polycarbonate hollow sheet must be installed and fixed with our company’s special anti-leakage upper and lower fasteners or the special flat strips provided by our company. If you use flat strips from other companies, you must ensure that the material of the strips is EPDM rubber or butyl rubber.

It is strictly forbidden to use polyvinyl chloride (PVC), natural rubber and other strips containing substances harmful to the polycarbonate hollow sheet.

5. When installing the hollow polycarbonate sheet, the side of the board with the UV co-extruded anti-uv layer and the text on the protective film must face the outside. Do not install it upside down. Remove the protective film immediately after installation to avoid adhesion between the protective film and the hollow polycarbonate sheet after exposure to the sun.

6. Before installing the sun board, the protective film about 30mm away from the edge should be removed. It is strictly forbidden to press the protective film under the profile and then cut the protective film with a knife. There should be no scratches on any part of the polycarbonate hollow sheet.

7. The section of the hollow polycarbonate sheet should be sealed with aluminum foil tape or waterproof breathable tape to prevent water vapor, dust and small insects from entering the air, affecting the transparency and aesthetics of the polycarbonate hollow sheet.

Company Name: Baoding Xinhai Plastic Sheet Co.,ltd

Contact Person: Sale Manager

Email: admin@cnxhpcsheet.com

Phone/Wechat/Whatsapp: +8619932587617

Country: China

Website: https://www.xhplasticsheet.com/

Post time: Jul-31-2024