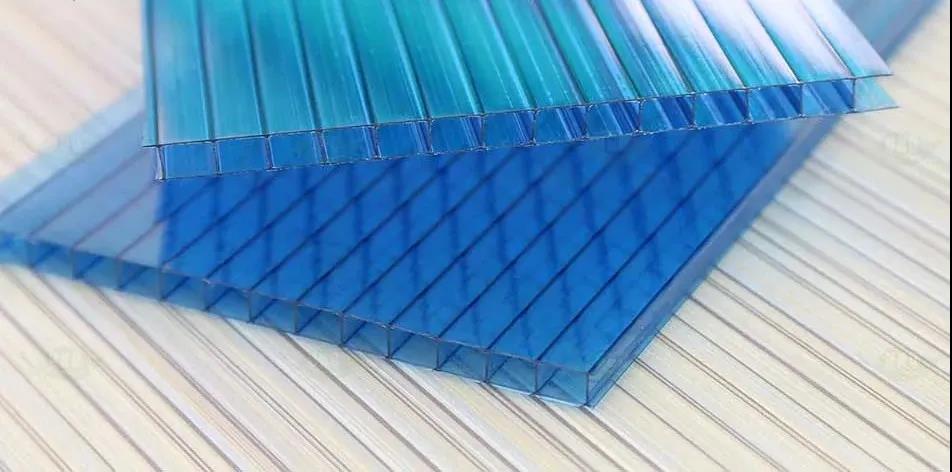

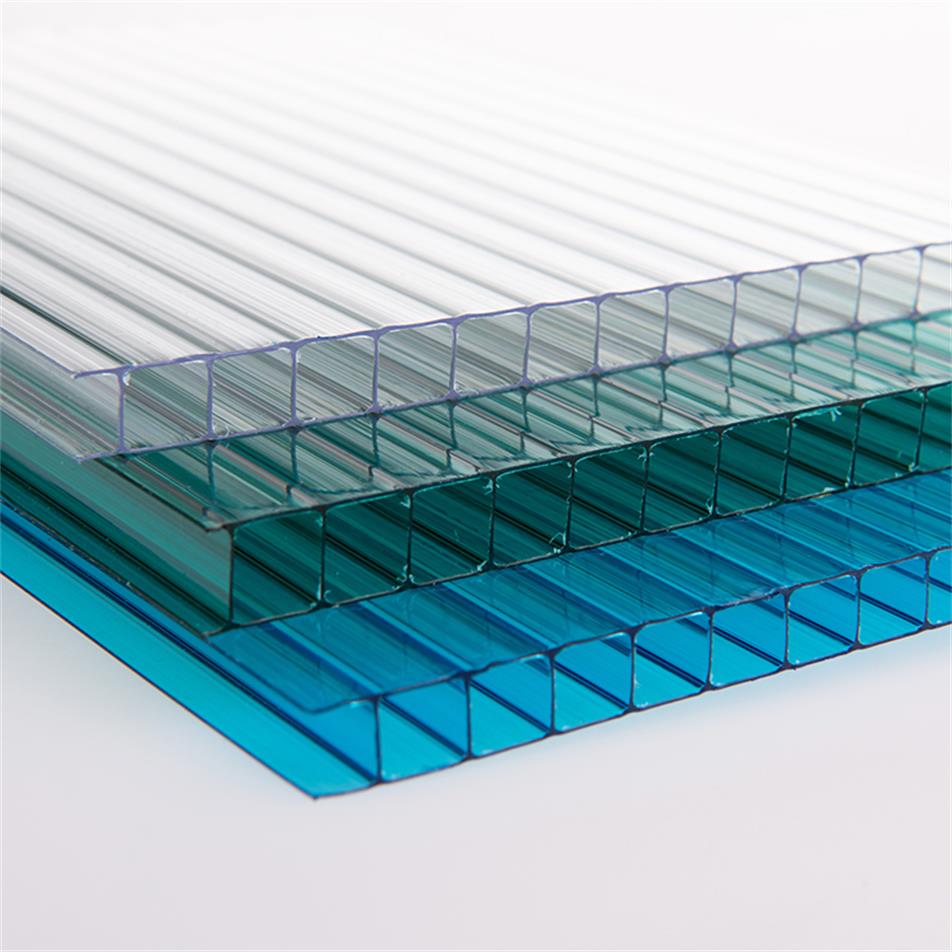

Polycarbonate hollow panels, also called lexan sheet or makrolon sheet, are made up of two or more single-layer sheet stacked in parallel and connected by reinforcing ribs. This structure determines that the production of polycarbonate panels requires the use of an extruder to continuously pass the heated raw material (polycarbonate) through the mold to extrude the sheet with the required cross-sectional shape, which is commonly referred to as the “extrusion method”. Although the principle of the extrusion method is simple, there are many production steps. Only after all is understood, can we pick out the panels that meet our own requirements and quality.

*Raw material drying

Polycarbonate is a resin that easily absorbs water, and the absorbed water will affect the physical properties of the board. There are two commonly used drying methods: pellet drying and extrusion exhaust.

*Add ingredients

Care should be taken to maintain stability and avoid stratification of different raw materials. Color masterbatch needs to be added to produce colored solar panels, and the color can be customized according to requirements.

*Extrusion filtration

A high temperature of nearly 300°C is required, and the temperature is increased in stages to ensure stability. Filter unplasticized solid particles to avoid defects such as “black spots” and “cold scars” on the sheet.

*Sheet forming

The molten material enters the mold after being extruded by the screw and stabilized. The mold is usually made of nickel-chromium-molybdenum steel, and its shape is the shape of the sheet to be formed. After the molten material passes through the mold, the sheet forming process is completed.

*Sheet shaping

Cooling the formed sheet to complete the initial shaping, and keeping the shaping device clean is the key to ensuring the smooth surface of the polycarbonate sheet. Pull out the preliminary shaped sheet with a traction roller, and finally shape the sheet after annealing to eliminate internal stress.

*Protective layer

The protective layer mainly includes an anti UV layer and an anti-fogging layer. The UV protection layer is formed by co-extrusion of a masterbatch containing an uv absorber and a polycarbonate sheet material. The anti-fogging layer can be directly coated on the surface of the sheet.

*Film cutting

The hollow polycarbonate sheet has very poor wear resistance. After the extrusion is completed, in order to prevent scratches, it is necessary to apply a protective film to the board and print the relevant product information on the board. Cut the plate to the required length as required.

*Closed package

After cutting the board, immediately seal the cut surface with self-adhesive tape to avoid contamination of the board cavity. After packaging with corrugated cardboard and white low-density polyethylene film in turn, the sunshine board can be shipped out.

Therefore, it is not difficult to see that the extrusion method can produce continuous sheets along the extrusion direction, and then cut them according to the actual required length to obtain the final product. The cross-sectional form of the sunshine board is different due to the difference of the selected extrusion die. The color of the board is determined by the different color masterbatches added to the raw materials. The product’s anti-ultraviolet, self-cleaning, anti-fogging and other properties are obtained by attaching the corresponding coating to the surface of the board.

Therefore, certain characteristics of the solar panels can be controlled by changing the processing procedures or production conditions, and the final performance of the panels can be deeply customized according to the actual needs of users.

SINHAI sales staff will answer your questions online 24 hours a day, welcome to customize high-quality polycarbonate sheets.

Company Name: Baoding Xinhai Plastic Sheet Co.,ltd

Contact Person: Sale Manager

Email: admin@cnxhpcsheet.com

Phone: +8617713273609

Country: China

Website: https://www.xhplasticsheet.com/

Post time: Sep-26-2021