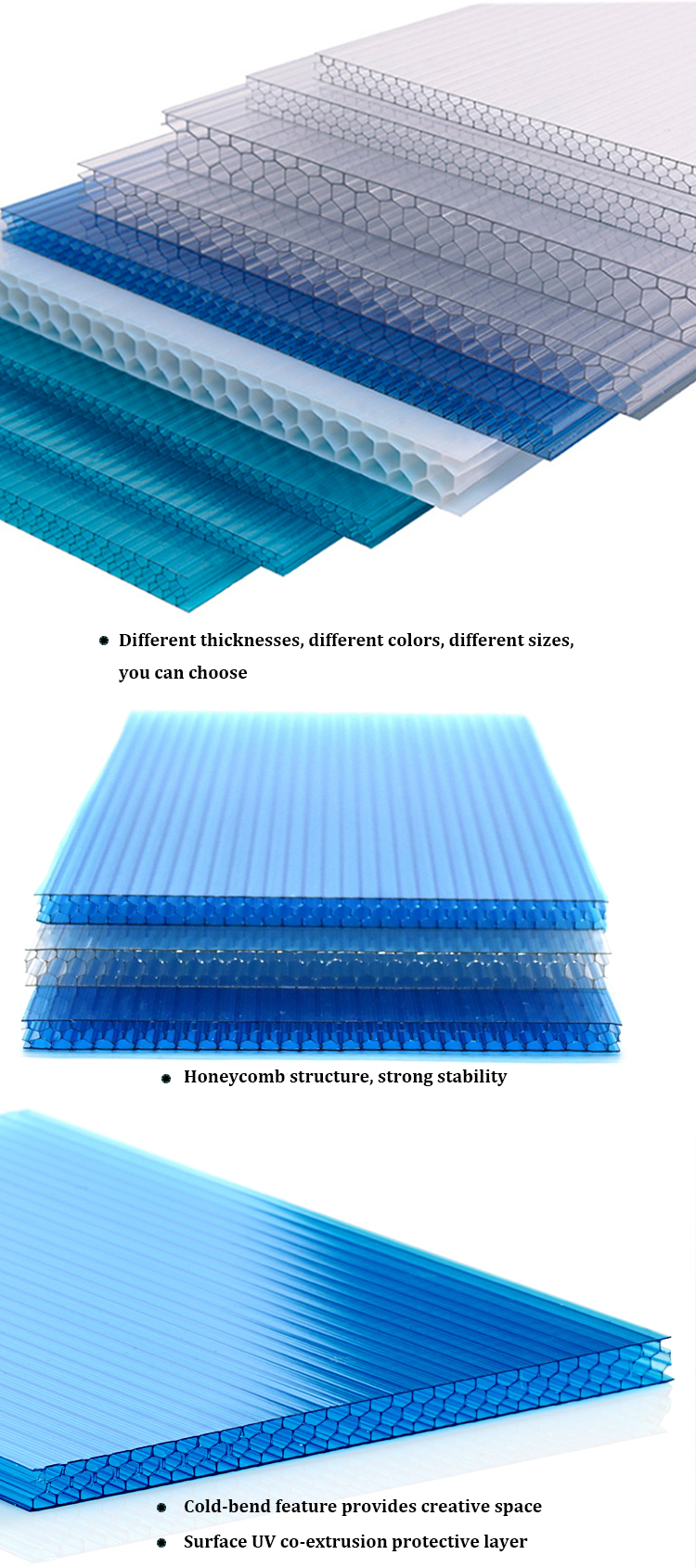

Honeycomb polycarbonate sheet, a porous sheet, has many advantages such as stable structure, low material consumption, wide coverage, high strength and light structure. The honeycomb core with six-sided columns connected to each other is like countless I-beams. The core layer is distributed and fixed in the entire board surface, making the board more stable, more resistant to bending and compression, and its wind pressure resistance is much better than that of ordinary double-layer hollow polycarbonate sheets.

Honeycomb polycarbonate sheet product features

1. Light transmittance of honeycomb pc sheet: good lighting, transparency comparable to glass. UV coated sheet will not turn yellow, atomize, or have poor light transmittance when exposed to sunlight. After ten years, the light transmittance loss is only 6%, while the PVC loss rate is as high as 15%-20%, and the glass fiber is 12%-20%.

2. Honeycomb polycarbonate sheet anti-UV: One side of the polycarbonate sheet is coated with an anti-UV coating, and the other side has anti-condensation treatment, which combines anti-ultraviolet, heat insulation and anti-drip functions. It can block ultraviolet rays from passing through, and is suitable for protecting valuable artworks and exhibits from ultraviolet damage.

3. Honeycomb polycarbonate sheets are light in weight: their specific gravity is only 1/12 of that of ordinary glass, and they are not easy to break, saving the cost of transportation, handling, installation and supporting frames.

4. Honeycomb polycarbonate sheets are flame retardant: The national standard GB50222-95 confirms that polycarbonate panels are flame retardant level 1, i.e. B1. The ignition point of polycarbonate panels is 580 degrees Celsius, and they will extinguish themselves after leaving the fire. When burning, they will not produce toxic gases and will not contribute to the spread of fire.

5. Honeycomb polycarbonate sheets are bendable: they can be installed into arches, semicircular tops and windows by cold bending on site according to the design drawings. The minimum bending radius is 175 times the thickness of the sheet, and hot bending is also possible.

6. Honeycomb polycarbonate sheets are soundproof: polycarbonate panels have obvious sound insulation effects and better sound insulation than glass and acrylic panels of the same thickness. Under the same thickness conditions, the sound insulation of polycarbonate panels is 3-4DB higher than that of glass. It is the best material for highway sound barriers internationally.

7. Energy saving of honeycomb polycarbonate sheets: keep cool in summer and keep warm in winter. The thermal conductivity (K value) of the hollow polycarbonate sheet is lower than that of ordinary glass and other plastics. The heat insulation effect is 7%-25% higher than that of the same glass, and the heat insulation of the polycarbonate hollow sheet is up to 49%. As a result, the heat loss is greatly reduced. It is used in buildings with heating equipment and is a material.

8. Temperature adaptability of honeycomb polycarbonate sheets: The polycarbonate hollow sheet does not become cold and brittle at -100℃, does not soften at 135℃, and its mechanics and mechanical properties do not change significantly in harsh environments.

9. Weather resistance of honeycomb polycarbonate sheet: The hollow polycarbonate sheet can maintain the stability of various physical indicators in the range of -40℃ to 120℃. After 4000 hours of artificial climate aging test, the yellowing degree is 2, and the transmittance reduction value is only 0.6%.

10. Anti-condensation of honeycomb polycarbonate sheet: When the outdoor temperature is 0℃, the indoor temperature is 23℃, and the indoor relative humidity is lower than 80%, the inner surface of the material does not condense.

Company Name: Baoding Xinhai Plastic Sheet Co.,ltd

Contact Person: Sale Manager

Email: admin@cnxhpcsheet.com

Phone/Wechat/Whatsapp: +8619932587617

Country: China

Website: https://www.xhplasticsheet.com/

Post time: Aug-30-2024