As an ideal thermal insulation material, the polycarbonate hollow sheet is often used in the construction of sunrooms and greenhouses. However, in foggy weather, due to the surface tension of the polycarbonate hollow sheet, the fog will form small water droplets on the surface of the sheet and adsorb on the sheet. surface. There are also PC sheets made by special process of double-sided UV, which are suitable for special flower planting and environments with higher requirements for UV protection. As small water droplets continue to condense, fog droplets are formed, which will not only cause damage to the sheet, but also have some adverse effects on the interior. If you want to avoid it, you must prevent the formation of fog droplets. Applying anti-fog droplet coating is i effective way.

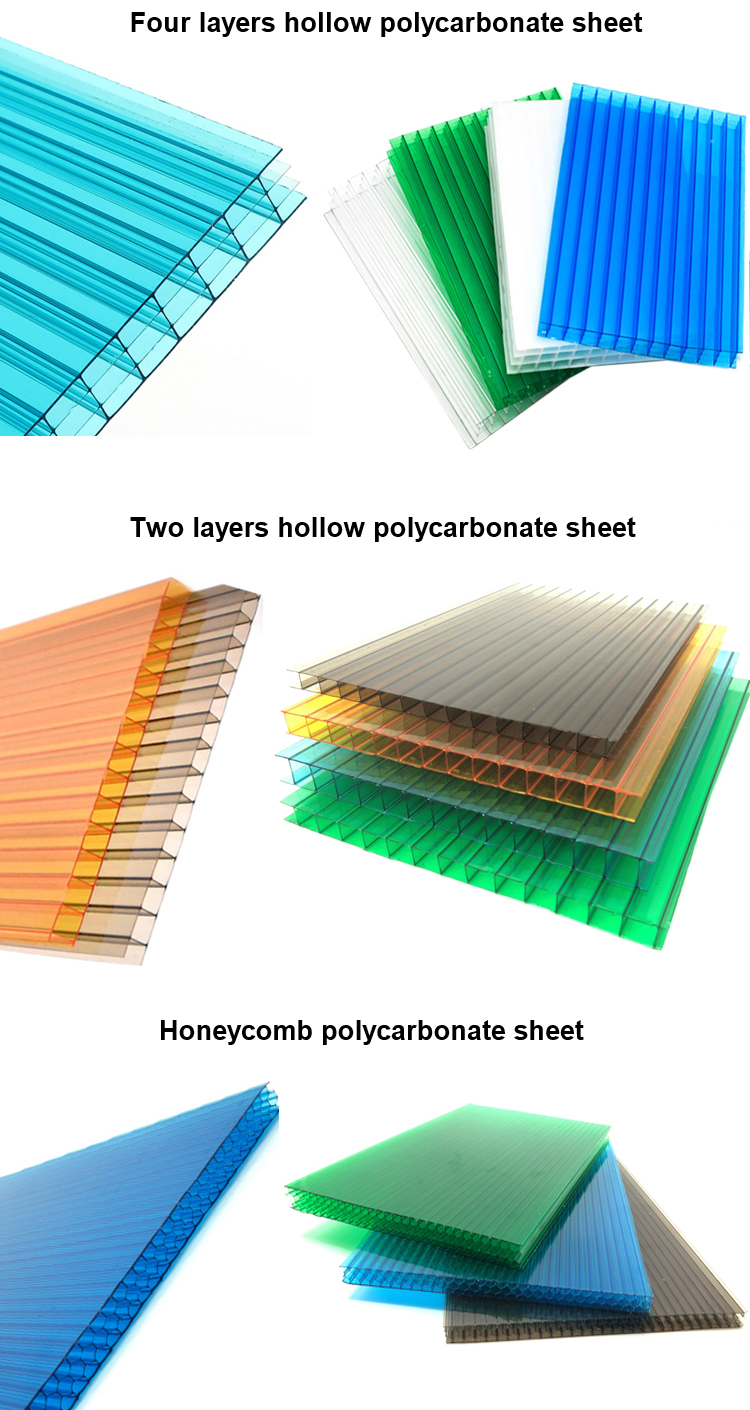

Specification and size of hollow polycarbonate sheet

The design of the polycarbonate hollow sheet is usually double-layer, and there are also multi-layer or special-shaped structures, but the most widely used is the double-layer structure. The polycarbonate hollow sheets with double-layer structure usually have thicknesses of 4mm, 6mm, 8mm, 10mm, 12mm, etc., and the length and thickness dimensions are 1220*2440mm,5800*210mm,6000*2100mm. Manufacturers can also make other specifications and shapes.

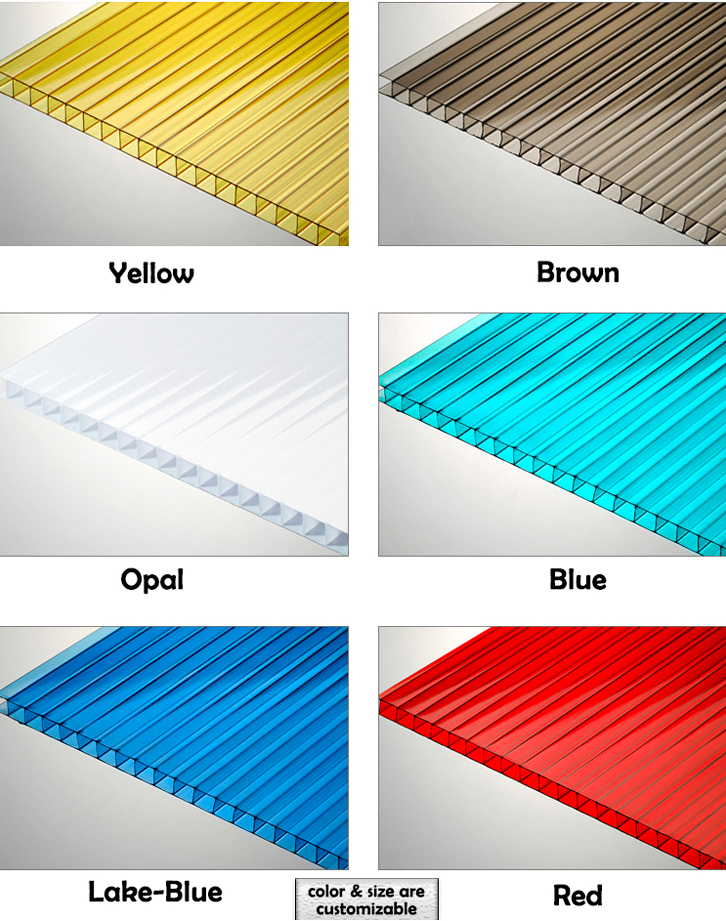

The colors of hollow polycarbonate panels include transparent, brown, milky white, red, lake blue and grass green. If the order area is large, you can contact the manufacturer to customize other colors. The light transmittance of the transparent polycarbonate hollow sheet is high, which can reach 80%, which is almost the same as that of glass. The light transmittance of grass green is low, if you need a strong shading effect, you can choose grass green.

Most of the PC hollow panels have a single-sided UV protective layer. If they are installed upside down, the polycarbonate hollow sheets will not be able to resist the invasion of ultraviolet rays, and they are prone to aging, yellowing, and embrittlement, which will seriously affect them.

During the installation process, we first transport the panels to the installation location, tear off the protective film at the bottom of the first panel, position it with a cap, then remove the protective film at the bottom of the second panel, position it with the cap, and connect the two panels Paste the waterproof tape on the place, and press the bead on the top of the waterproof tape.

Generally speaking, Polycarbonate hollow sheet products will have text instructions and precautions printed on the protective film, and installers need to read them carefully to avoid mistakes.

Company Name: Baoding Xinhai Plastic Sheet Co.,ltd

Contact Person: Sale Manager

Email: admin@cnxhpcsheet.com

Phone/Wechat/Whatsapp: +8619932587617

Country: China

Website: https://www.xhplasticsheet.com/

Post time: Aug-01-2023