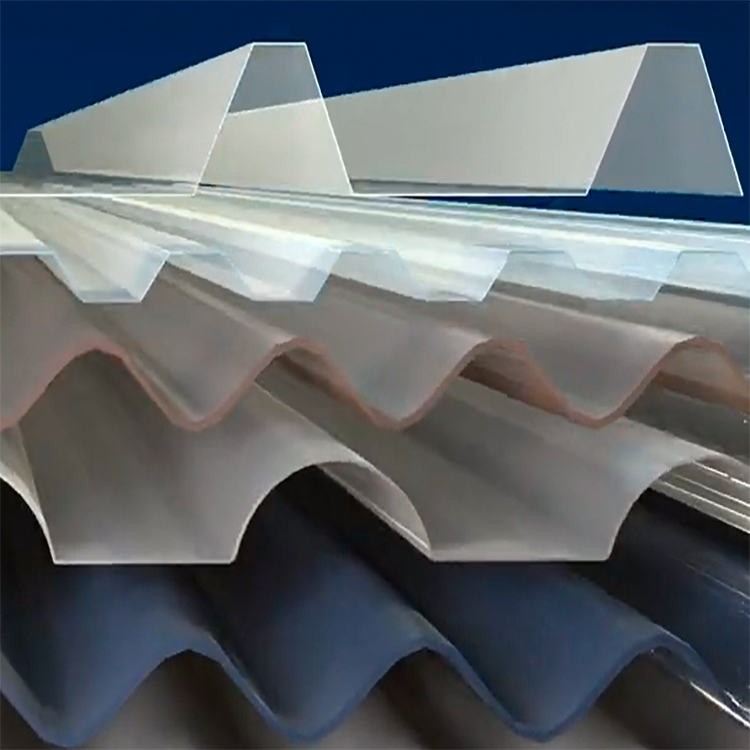

Polycarbonate corrugated wave tiles are widely used in international plastic building materials and other building decoration materials (such as glass, organic glass, etc.) with unparalleled advantages, and are known as “unbreakable glass”. It is a new type of high-quality decorative material with high strength, transparency, sound insulation, and energy conservation. Polycarbonate corrugated sheet is one of the synthetic resins with a low coefficient of linear expansion. The coefficient of linear expansion of the sheet varies slightly in different directions, with an average of 0.065mm/m. ℃. The thermal conductivity of Polycarbonate corrugated sheets is very different from that of general synthetic resins, which is 1/4 of glass, 1/300 of iron, 1/1000 of aluminum, and 1/12000 of copper. They are all good insulation materials.

The thermal conductivity of PC sheet is lower than that of plastics such as glass (K value), and the thermal insulation effect is 7% -25% higher than other glass. The thermal insulation of polycarbonate corrugated sheets is as high as 49%. It greatly reduces heat loss and is an environmentally friendly material used for construction heating equipment. Plants need appropriate temperature and humidity to grow. Correspondingly, corrugated polycarbonate sheet greenhouses require ventilation systems to regulate and control the temperature and humidity of the rooms, providing a suitable growth environment for plants. The general ventilation system for PC hollow sheet greenhouses can be divided into natural ventilation and forced ventilation.

The so-called natural ventilation is achieved by opening the side windows or skylights of the corrugated polycarbonate sheet greenhouse, utilizing the temperature difference or wind pressure of the polycarbonate greenhouse to achieve indoor and outdoor air convection, reducing the temperature and humidity of the hollow polycarbonate sheet greenhouse, and allowing the fog droplets from the hollow polycarbonate sheet to fall onto the polycarbonate hollow sheet. The so-called forced ventilation is to regulate the temperature and humidity of the hollow polycarbonate sheet greenhouse by starting fans such as polycarbonate wave tile greenhouse to force air convection. Both ventilation methods have their own characteristics and are suitable for different occasions.

As the area of individual hollow polycarbonate sheet greenhouses continues to expand, in order to improve the ventilation capacity of polycarbonate hollow sheet greenhouses, skylights have a much better effect than side windows. With the help of the window opening system, the side windows and skylights of the greenhouse can be opened or closed as needed. The side windows of a polycarbonate hollow sheet greenhouse are usually continuous windows. If the hollow polycarbonate sheet greenhouse is covered with hard materials such as glass and PC sheet, it is driven by a continuous gear rack system; If it is a soft material such as roll film, a roll film window system can be used. Another option is to use inflatable polyester windows, which can be closed or opened by inflating or deflating the airbags. The skylight of the greenhouse can be designed to open continuously or intermittently along the roof ridge of the greenhouse.

In the building materials market, it is common to see many low-quality endurance boards. After application for a period of time, the transparent head drops significantly faster, and obvious cracks and even brittleness can be seen on the surface, all of which are obvious signs of aging of the sheet.

Extending the aging time of the lifespan sheet is equivalent to extending its service life. In addition, the lifespan of solid polycarbonate sheets is directly related to the raw materials, and the number of raw material molecules that fail to reach the machine during the production process can also affect the lifespan of the sheets.

Company Name: Baoding Xinhai Plastic Sheet Co.,ltd

Contact Person: Sale Manager

Email: admin@cnxhpcsheet.com

Phone/Wechat/Whatsapp: +8619932587617

Country: China

Website: https://www.xhplasticsheet.com/

Post time: Apr-26-2024