SINHAI Siv Cov Khoom Siv Yas Lexan UV tiv thaiv hollow polycarbonate ntawv

Product Detail

Qhov kub ntawm qhov kub thiab txias ntawm PC polycarbonate ntawv yog 630 ℃.Raws li kev ntsuam xyuas ntawm National Fireproof Building Material Quality Supervision and Inspection Center, PC ntawv muaj qhov sib kis ntawm GB, uas yog cov khoom siv hluav taws xob tsis zoo.Tshuaj tiv thaiv corrosion.Polycarbonate hollow daim ntawv muaj cov tshuaj zoo tiv thaiv corrosion, thiab tuaj yeem tiv taus kev yaig ntawm ntau cov organic acids, inorganic acids, qaug zog acids, zaub roj, nruab nrab ntsev daws, aliphatic hydrocarbons thiab cawv ntawm chav tsev kub.Kub thiab txias tsis kam.Cov ntawv lexan polycarbonate muaj qhov kub thiab txias tsis kam, tuaj yeem hloov kho rau ntau yam huab cua hloov pauv los ntawm qhov txias txias mus rau qhov kub thiab txias, thiab tswj ntau yam kev ntsuas lub cev nyob rau hauv thaj tsam ntawm -40 ° C txog + 120 ° C.Photochemical.PC hollow daim ntawv muaj lub teeb pom kev zoo tshaj plaws nyob rau hauv lub teeb pom kev thiab ze-infrared spectrum.Nyob ntawm cov xim, lub teeb xa tawm tuaj yeem ncav cuag 12% -88%.Anti-uv thiab anti-aging.Qhov saum npoo ntawm daim ntawv hollow polycarbonate muaj cov txheej txheem los tiv thaiv uv co-extruded, uas muaj cov huab cua zoo sab nraum zoov thiab tuav cov khoom kho qhov muag zoo thiab cov khoom siv kho qhov muag tom qab siv mus ntev.Daim ntawv ntxaib phab ntsa polycarbonate yog lub teeb hauv qhov hnyav, 1/12-1/15 ntawm tib lub iav, muaj kev nyab xeeb thiab tsis tawg, yooj yim los tuav thiab txhim kho, tuaj yeem txo qhov hnyav ntawm lub tsev, ua kom yooj yim rau cov qauv tsim, thiab txuag nqi installation .

| Khoom siv | 100% nkauj xwb bayer / sabic polycarbonate cob |

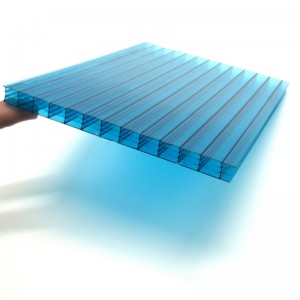

| Thickness | 2.8mm-12mm |

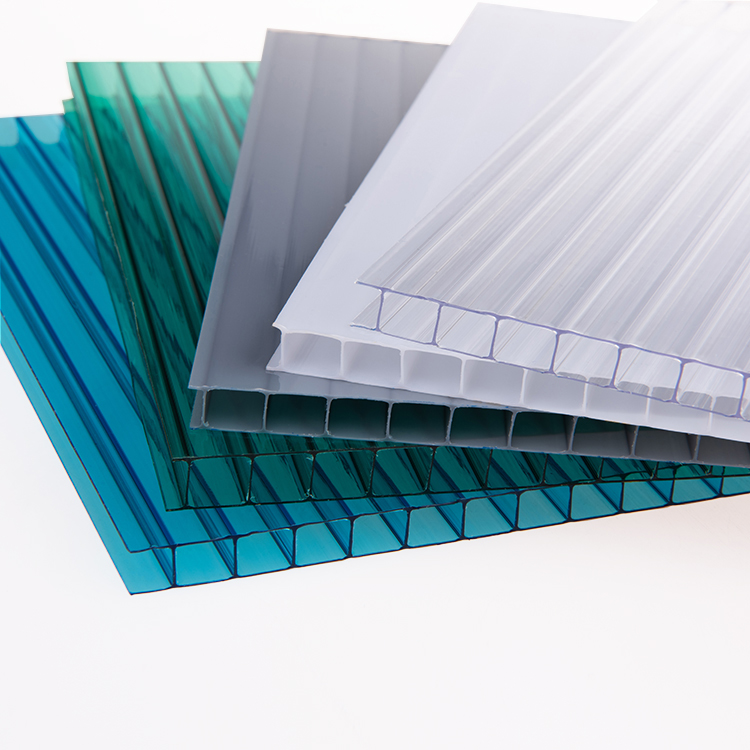

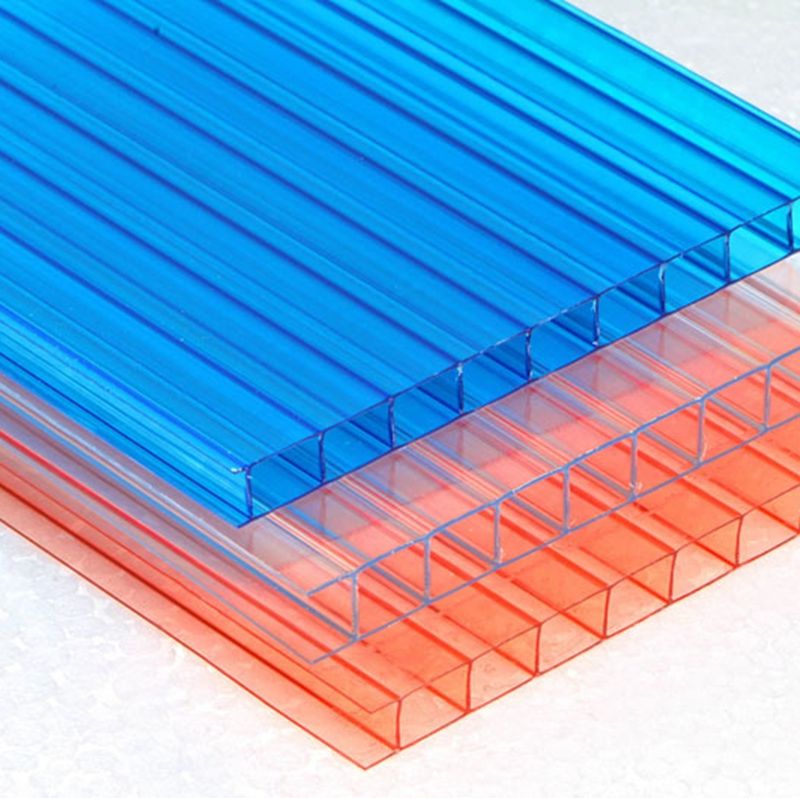

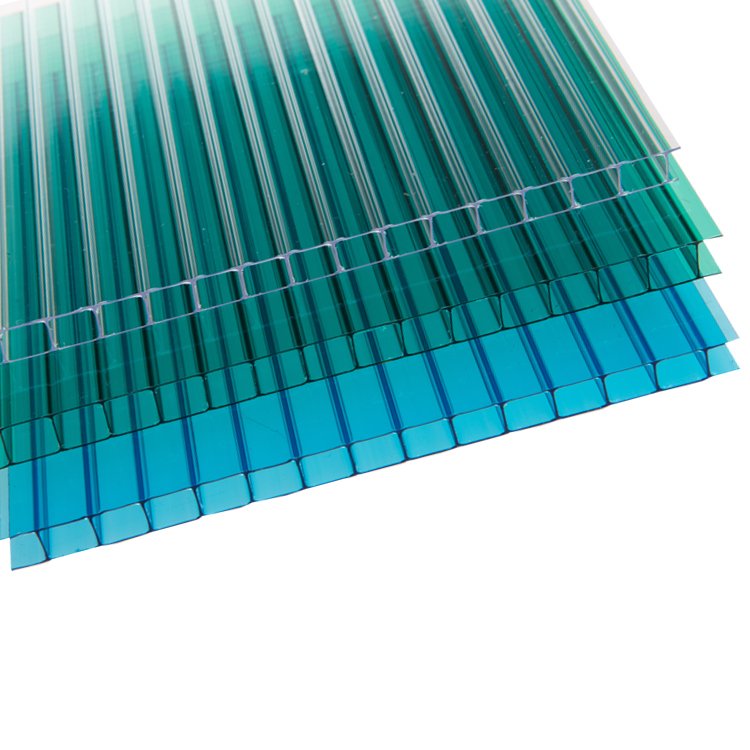

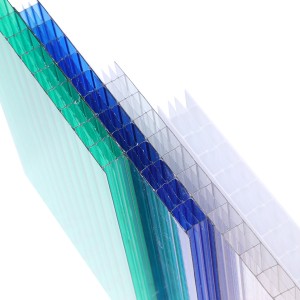

| Xim | Ntshiab, Xiav, Lake Blue, Ntsuab, Bronze, Opal lossis Customized |

| Dav | 1220, 1800, 2100mm los yog customized |

| Ntev | Tsis txwv |

| Warranty | 10-Xyoo |

| Technology | Co-extrusion |

| Nqe lus | EXW/FOB/C&F/CIF |

| Thickness (hli) | Qhov hnyav (kg / m²) | Dav (mm) | U Tus nqi (w / m²) | Lub teeb kis tau tus mob (%) ntshiab | Min khoov radiums (mm) | Min ncua (mm) |

| 4 | 0.95 ib |

1220/2100 Nws

| 3.96 ib | 78 | 700 | 1500 |

| 6 | 1.3 | 3.56 ib | 77 | 1050 | 1800 | |

| 8 | 1.5 | 3.26 | 76 | 1400 | 2000 | |

| 10 | 1.7 | 3.02 Nws | 73 | 1750 | 2700 ib |

| UM | PC | PMMA | PVC | PET | GRP | GLASS | |

| Qhov ntom | g/cm³ | 1.20 | 1.19 | 1.38 ib | 1.33 | 1.42 ib | 2.50 Nws |

| Lub zog | KJ/m² | 70 | 2 | 4 | 3 | 1.2 | - |

| Modulus ntawm elasticity | N / mm² | 2300 | 3200 | 3200 | 2450 | 6000 | 70000 |

| Linear thermal expansion | 1 / ℃ | 6.5 × 10-5 | 7.5 × 10-5 | 6.7 × 10-5 | 5.0 × 10-5 | 3.2 × 10-5 | 0.9 × 10-5 |

| Thermal conductivity | W/mk | 0.20 ib | 0.19 ib | 0.13 | 0.24 ib | 0.15 | 1.3 |

| Max.service kub | ℃ | 120 | 90 | 60 | 80 | 140 | 240 |

| UV pob tshab | % | 4 | 40 | nd | nd | 19 | 80 |

| Hluav taws ua haujlwm | - | zoo heev | pluag | zoo | zoo | pluag | hluav taws kub |

| Resistance rau huab cua | - | zoo | zoo heev | pluag | ncaj ncees | pluag | zoo heev |

| Tshuaj compatibility | - | ncaj ncees | ncaj ncees | zoo | zoo | zoo | Zoo heev |