Bottom price frosted polycarbonate sheet - SINHAI UV protection hollow polycarbonate sheet for roofing – Sinhai

Bottom price frosted polycarbonate sheet - SINHAI UV protection hollow polycarbonate sheet for roofing – Sinhai Detail:

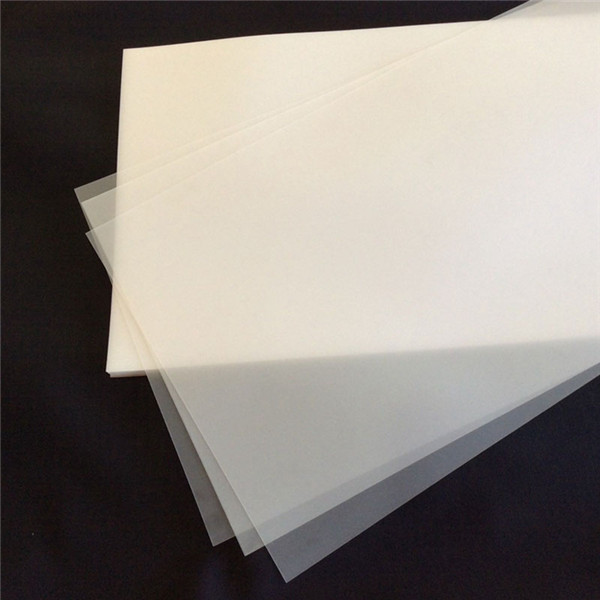

UV-coated polycarbonate sheets will not produce yellowing, atomization, and poor light transmission under sunlight. After ten years, the loss of light transmission is only 10%, the loss rate of PVC is as high as 15%-20%, and the glass fiber is 12 %-20%.

Anti-UV: One side of the PC board is co-extruded with an anti-ultraviolet (UV) coating, and the other side has an anti-condensation treatment, which integrates anti-ultraviolet, heat insulation and anti-fogging functions. It can block ultraviolet rays from passing through, and is suitable for protecting valuable artworks and exhibits from damage by ultraviolet rays.

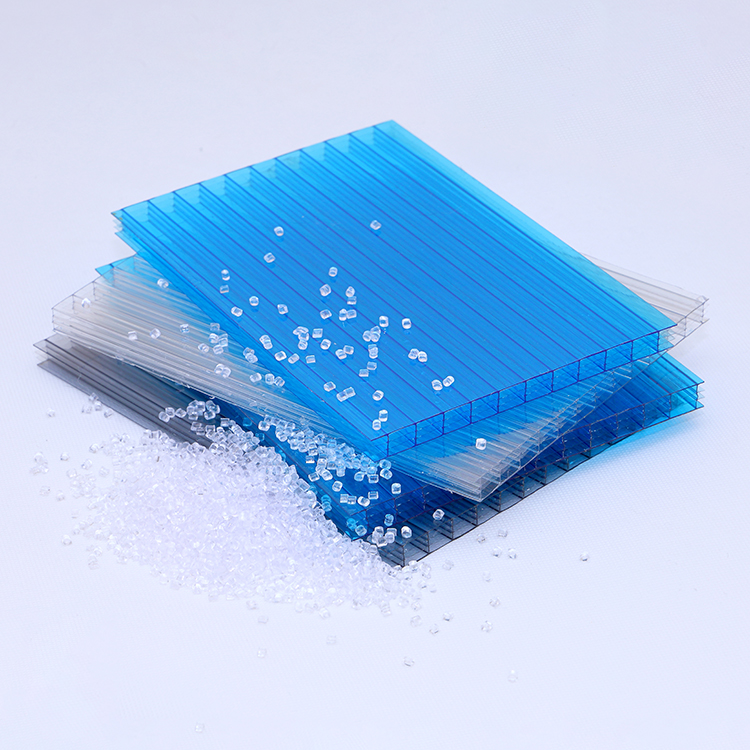

| Material | 100% virgin bayer/sabic polycarbonate resin |

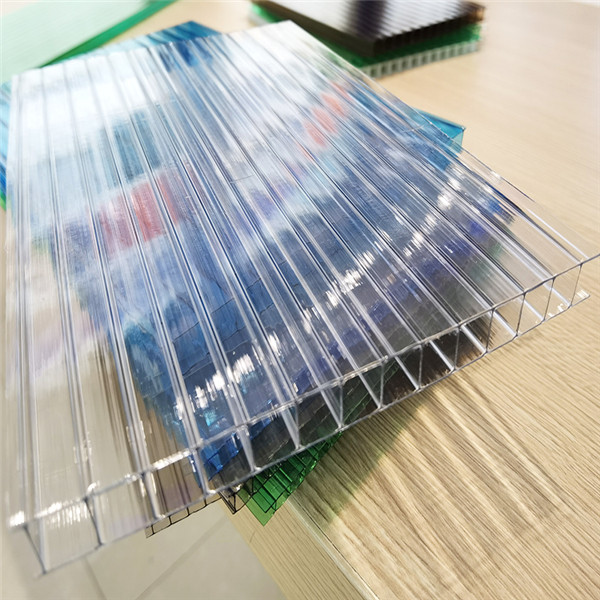

| Thickness | 2.8mm-20mm |

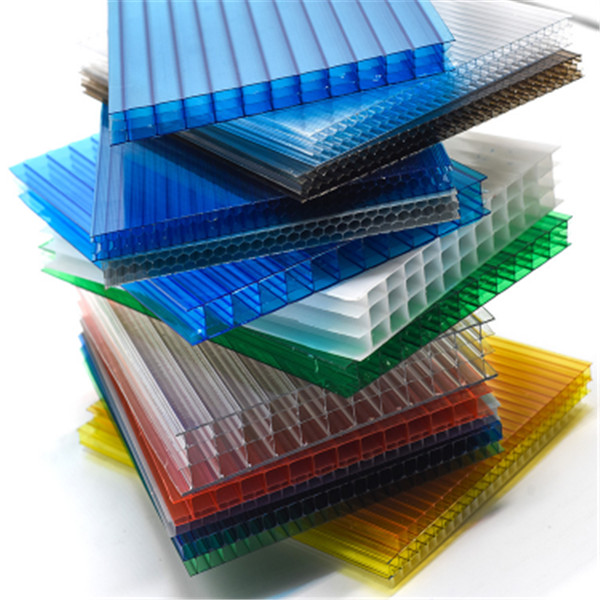

| Color | Clear, Blue, Lake Blue,Green, Bronze, Opal or Customized |

| Width | 1220, 1800, 2100mm or customized |

| Length | No limit |

| UV protective layer thickness | Usually 50μm, can be added according to your project needs |

| Warranty | 10-Year |

| Technology | Co-extrusion |

| Price term | EXW/FOB/C&F/CIF |

| Port | Tianjin |

| Payment | By T/T,L/C,Paypal |

| Delivery Time | Within 3-10 working days according to the quantity |

| Packaging | Both sides with PE film, logo on the PE film. Film logo is available to design for free |

Product Data

|

Product Data |

|||||

| No | Item | Data | No | Item | Data |

| 1 | Impact Strength | 850 J/M | 7 | Flexural Strength | 100 N/mm² |

| 2 | Specific Grevity | 1.2 g/cm³ | 8 | Modulus of Elasticity | 2400 Mpa |

| 3 | Coefficient of Thermal Expansion | 0.065 mm/m℃ | 9 | Tensile Stress at Break | ≥65 Mpa |

| 4 | Service Temperature | -40℃~120℃ | 10 | Elongation at break | 100% |

| 5 | Heat Conductivity | 2.3-3.9 w/m²℃ | 11 | Heat Deflection Temperature | 140 ℃ |

| 6 | Tensile Strength | ≥60 N/mm² | 12 | Specific Heat | 1.17 k.J/kg.K |

Product Feature

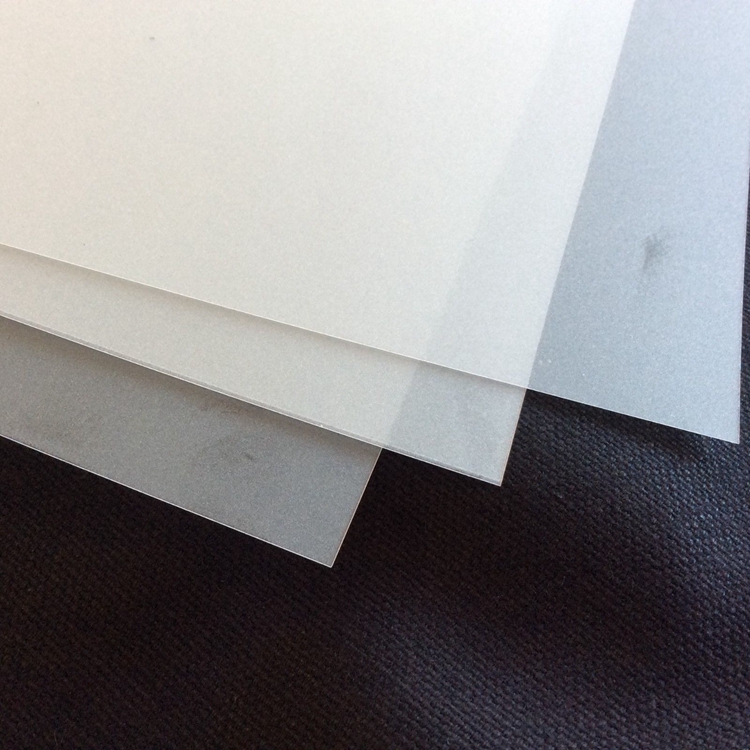

Comparison of acrylic sheet and polycarbonate sheet with UV coating on the surface: After three years of wind and sun, the surface of the acrylic sheet has turned yellow, while the uv protection polycarbonate sheet is still transparent after three years of use.

Product Application

Due to the anti-ultraviolet coating added to the surface of the board, applying the board outdoors can prevent direct sunlight, resulting in a short life of the sun board. The board will not turn yellow and become brittle due to the anti-ultraviolet coating. Can be widely used in carport, roofing cover, awning, curtain wall, cannopy

Product detail pictures:

Related Product Guide:

The last two years,the global polycarbonate sheet market is in a leading position in terms of demand, revenue and business growth

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Bottom price frosted polycarbonate sheet - SINHAI UV protection hollow polycarbonate sheet for roofing – Sinhai , The product will supply to all over the world, such as: San Diego , Uganda , Bangalore , Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!